Idayimani isarha blade, isixhobo esine-blade esisetyenziswa ngokuqhelekileyo ukusika i-aluminium yebhulorho, i-acrylic kunye nelitye.Kwimbali yonke yokusika isinyithi, ukuvela kwee-diamond saw blades kuye kwahlawula ngokufanelekileyo iimpazamo ezininzi ze-alloy alloy saw blades kunye ne-carbon steel saw blades.

Ukusebenza okugqwesileyo kokusika kuyinzuzo yendalo yeesarha zedayimani, kwaye ngenxa yokusetyenziswa kwamazinyo edayimani aqina nangakumbi anganyangekiyo ubushushu, ixesha lokuphila kweesaha zedayimani nalo lide kakhulu.

Xa kuthelekiswa nee blades zesarha zealloyi eziqhelekileyo, ubomi becala lesarha yedayimani budla ngokuba ziinyanga ezininzi ubude.Ewe, zininzi izinto ezichaphazela ixesha lokuphila kwee-diamond saw blades.

Ukongeza kumgangatho we-saw blade ngokwayo, kwinkqubo yokuvelisa ngokwenene, ukusetyenziswa kwee-diamond saw blades kunye nokuba umsebenzi womqhubi usemgangathweni, kunye nobunzulu kunye nesantya somgca wesondlo, kuya kuchaphazela ubomi benkonzo idayimani isarha blade.

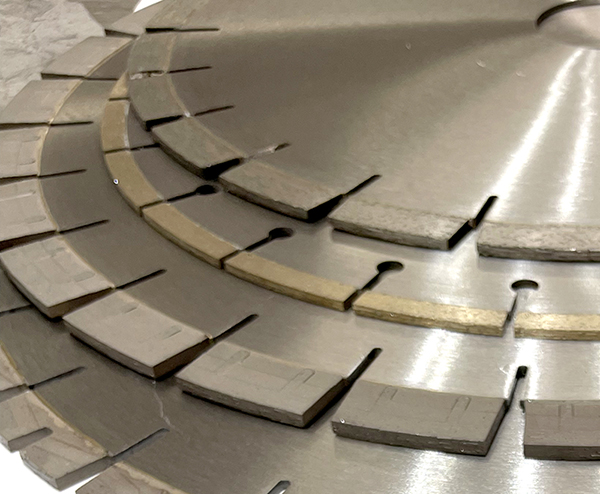

Okwangoku, kukho iindlela ezine eziqhelekileyo ezisetyenziswayo ukwenzaiincakuba zesarha yedayimani, kubandakanywa indlela yokucofa okubandayo, indlela ye-welding eshushu, indlela yokuqengqeleka, kunye nendlela yokufaka izinyo.

Indlela yoku-1: Indlela yokucofa okubandayo

Ubukhulu becala lesarha yedayimane eyenziwe ngendlela yokucofa okubandayo ingaphantsi kweemilimitha ezingama-400 ngenxa yobuchwephesha bokuvelisa.

Ngeli xesha, indlela yokucofa okubandayo ye-sintering ine-advanteji yeendleko eziphantsi zemveliso, ngakumbi kwiiblades ezithile ezimanzi.Kwinkqubo yokuvelisa, indlela ye-welding ebandayo isetyenziswa ngokubanzi.

Iidayimani isarha bladeukusebenzisa le nkqubo yokuvelisa isoloko iqinisekisa ukusebenza okuzinzileyo xa usika iiprofayili ezinzima ezifana negranite, umhlaba oxubeneyo onzima, i-asphalt, njl.

Indlela yesi-2: Indlela ye-welding ye-Hot press

Kumashishini avelisa i-diamond saw blades, ukwenzela ukuba kuqinisekiswe imveliso ezinzileyo, bahlala bekhetha indlela ye-welding eshushu yokushicilela okwangoku.

Le ndlela yokuvelisa ii-diamond saw blades ngoku yeyona ndlela idumileyo.Ngeli xesha, xa kuthelekiswa nendlela yokuwelda ebandayo, le ndlela yokuvelisa inokuvelisa iincakuba zesarha zedayimani ezinobubanzi obukhulu.

Uluhlu lwedayamitha ngokubanzi luphakathi kwe-350 millimeters kunye ne-2200 millimeters, kwaye ezinye iiblade zedayimani ezinkulu, ezifana nezo zisetyenziselwa ukusika amatye, zisebenzisa le nkqubo kwinkqubo yokuvelisa.Iinkqubo ezisisiseko zokuvelisa ziquka ukuxuba, ukucofa okutshisayo, ukugaya i-arc, i-welding, kunye nokusika.

Indlela yesi-3: Indlela yokuqengqeleka

Idayimani yabona iincakubaeveliswa ngendlela yokuqengqeleka inexabiso eliphantsi lokwenziwa kwexabiso, kwaye iiblade zedayimani eziveliswe yile nkqubo yokwenziwa ziqhele ukusetyenziselwa izinto zokusarha ezifana newotshi, amatye anqabileyo, iibheringi, njl.

Incakuba yesarha yedayimani eyenziwe kusetyenziswa le ndlela ngokuqhelekileyo yenziwe ngentsimbi yesinyithi, enobubanzi obuphakathi kwe-80-120 yeemilimitha kunye nobukhulu obuphakathi kwe-0.2-0.4 yeemilimitha.

Indlela yesi-4: Indlela yokuFaka iGear

Njengoko igama libonisa, indlela yokufaka i-inlay kukuzinzisa iisarha zedayimani kwisihlalo sezinyo sesarha yesarha.I-diamond isarha blade eveliswe yile nkqubo yokuvelisa incinci, kunye ne-sawteeth ibonakala ingaqhubeki kwisangqa sangaphandle kwaye ifakwe ngokuqinileyo kumphetho wevili.Ukusika kubukhali kwaye iitshiphusi zilula ukususa.

Kwangaxeshanye, iingenelo zokusebenzisa le nkqubo yokwenziwa kwee-saw blades kukusebenza kakuhle kokusika, ukulahleka kwezinto eziphantsi, kunye nokukwazi ukusika izinto ezibhityileyo.Oku kungenxa yokuba ukongeza kwintsimi yamatye, ii-blades zesarha ezenziwe kusetyenziswa le nkqubo zikwasetyenziswa kwintsimi yokucubungula iprofayili ye-aluminium.

Okwangoku, kungakhathaliseki indlela yokuvelisa esetyenzisiweyo, inokuqinisekisa ngokufanelekileyo umgangatho wee-diamond saw blades kunye neeprofayili zokusika.Xa kuziwa kwiiprofayili ze-aluminiyam, ngenxa yenkqubo yokuvelisa ephucukileyo, ukusebenza kokusika kwe-saw blade kuhle kakhulu.

Ukongeza, ngenxa yeempawu ezibalaseleyo zokusika isinyithiiincakuba zesarha yedayimani, zinokucolwa ngokuphindaphindiweyo.

Xa kuthelekiswa ne-alloy hard alloy saw blades ezinokugudiswa kuphela amaxesha angama-1-2 ebomini,iincakuba zesarha yedayimaniinokugudiswa amaxesha angama-6-8 ebomini.Kumashishini, kuthetha ukwamkela indlela yokugaya, enokugcina ixabiso elikhulu leendleko zeendleko.

Ixesha lokuposa: Dec-14-2023