1, Yintoni iidayimani isarha isarha setyhula

Isarha yesarha esetyhula yedayimanisisixhobo sokusika esisetyenziswa ngokuqhelekileyo, esinencakuba yesarha enomphetho wokusika wedayimane obekwe kwisangqa sangaphakathi okanye sangaphandle sesarha.Isetyenziswa ngokubanzi ekusetyenzweni kwezinto eziqinileyo kunye nezinqabileyo ezifana namatye kunye neekeramics.I-diamond saw blade iquka iinxalenye ezimbini: i-substrate kunye ne-blade.I-substrate iyona nxalenye ephambili yokuxhasa i-adhesive blade, ngelixa i-blade inxalenye yokusika eqala ngexesha lokusetyenziswa.I-blade iya kudla ngokuqhubekayo ngexesha lokusetyenziswa, ngelixa i-substrate ayiyi.Iincinci zeDayimane zihlanganiswe ngetsimbi ngaphakathi kwentloko yokusika, edlala indima yokusika kwi-friction cut of the processed process ngexesha lomatshini.Ngexesha lokusetyenziswa, i-matrix yesinyithi kunye nedayimane idliwe kunye.Ngokuqhelekileyo kulungele ukuba i-matrix yensimbi idle ngokukhawuleza kunedayimane, eqinisekisa ukuba zombini ubukhali bentloko yokusika kunye nobomi benkonzo yentloko yokusika.

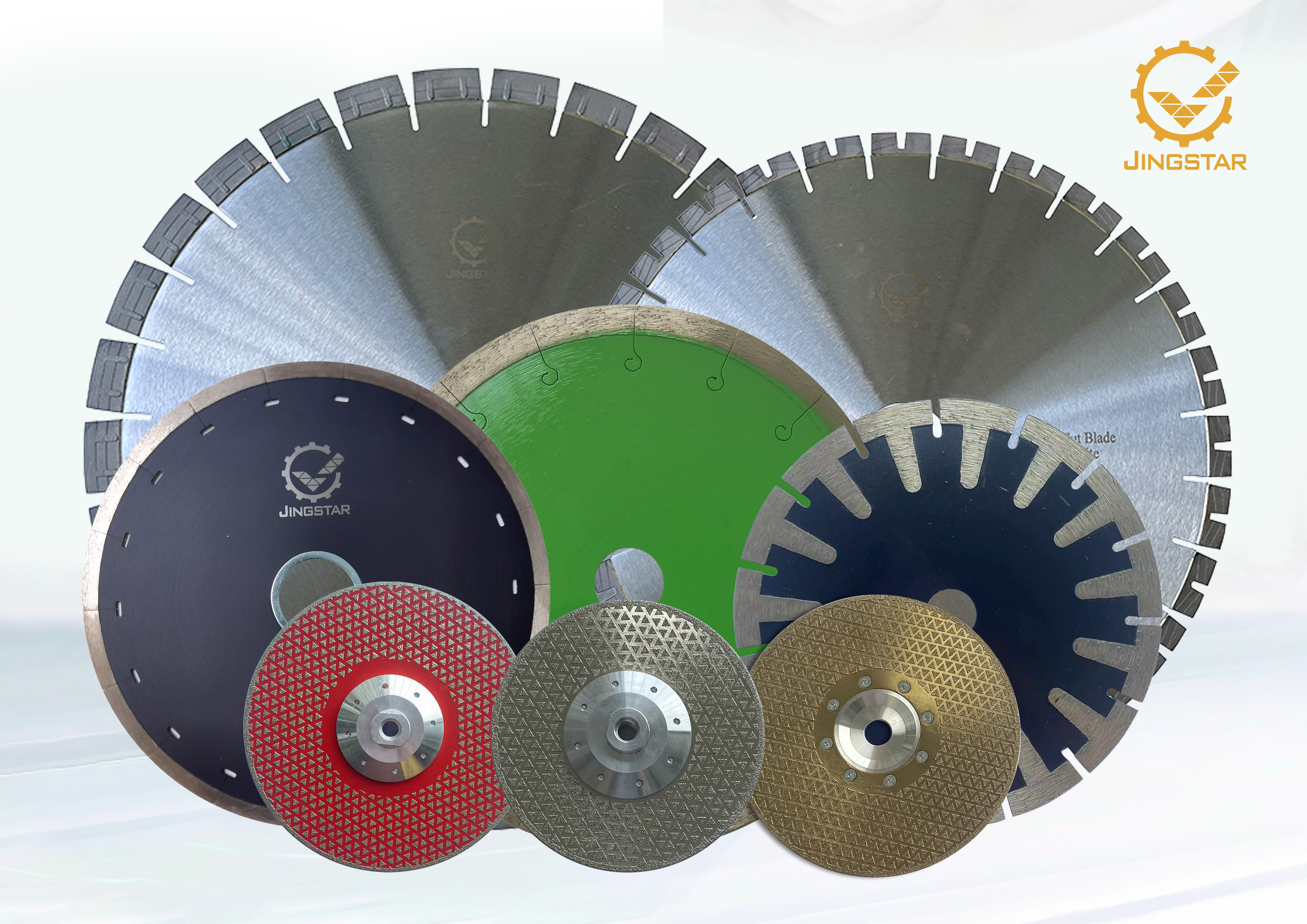

Ubude bedayamitha yeiincakuba zesarha zedayimani ezijikelezayoinkulu, inamacangca okukrola amalunga neemilimitha ezininzi kunye neesarha ezinkulu eziziimitha eziliqela ububanzi.Kukho nezinto ezininzi zokusika, kwaye isakhiwo, ubunzima, kunye nobukhulu bezinto zokusika ziyahluka kakhulu.Ke ngoko, ukusetyenzwa kwabo kunye neendlela zokwenza, izinto ezisetyenziswayo, kunye neemfuno zokusetyenziswa zahlukile.

2、 Ukuhlelwa kweiincakuba zesarha zedayimani ezijikelezayo

Isarha yesarha esetyhula yedayimaniokwangoku sesona sixhobo sisetyenziswa ngokuxhaphakileyo kwishishini lamatye laseTshayina, eliqheleke njengesetyhula ngokwemilo.Isebenzisa iindlela ezinje ngomgubo wesinyithi okanye i-electroplating ukushumeka amasuntswana edayimani ajikeleze i-substrate.Ukusebenzisa amandla aphezulu kunye nokuqina kwamasuntswana edayimani ukucheba kunye nokutyumza ezinye izinto ngeenjongo zokusika.Kukho iintlobo ezininziiincakuba zesarha zedayimani ezijikelezayokwaye nokuhlelwa kwazo kuntsonkothile kakhulu.Ngokuqhelekileyo kukho iindlela ezininzi zokuhlela:

1. Ukuhlelwa ngokwenkqubo yokuvelisa:

(1) Incakuba yesarha yedayimani enyibilikayo

Kukho iindidi ezimbini zokucofa: ukucofa okubandayo kunye ne-hot sintering.

(2) Intsimbi yesarha yedayimani yokuwelda

Zimbini iintlobo zokugalela kunye ne-Laser beam welding.I-Brazing idibanisa intloko ye-cutter kunye ne-substrate kunye ngokusebenzisa i-high-frequency melting medium, njenge-high-frequency induction brazing saw blade, i-vacuum brazing saw blade, njl.I-laser welding isebenzisa ubushushu obuphezulu be-laser beam ukunyibilikisa intloko yokusika kunye nomda wokudibanisa we-substrate ukwenza i-metallurgical bonding.

(3) Incakuba yesarha yedayimani ene-electroplated

Yinkqubo yokudibanisa i-blade powder kwi-substrate ngokusebenzisa i-electroplating.Nangona kunjalo, ngenxa yongcoliseko olumandla, ilizwe liyayiphelisa ngokuthe ngcembe le ndlela yokucoca i-electroplating.

2. Ukuhlelwa ngokusetyenzwa kwento:

I-marble cutting saw blade, i-granite cutting saw blade, i-concrete cutting saw blade, njl.

3. Ukuhlelwa ngokwenkangeleko:

Iincayidi zeesarha eziqhubekayo, uhlobo lwencakuba yeesarha iincakuba, uhlobo lweesarha zohlobo lwe turbine, njl.iincakuba zesarha zedayimani ezijikelezayo, kwaye kukwakho neenjongo ezininzi ezikhethekileyoiincakuba zesarha zedayimani ezijikelezayo.Khetha iindidi ngeencakuba zeesarha zedayimani ukuze kulungiswe izinto ezahlukeneyo.

3, Iimpawu eziphambili zeidayimani isarha isarha setyhulaukusika

Isetyhula yokusika iblade yesarha ineengenelo zokusebenza ngokulula, ukusebenza kakuhle okuphezulu, kunye nomgangatho wokusetyenzwa kakuhle.Kodwa ingxolo iphezulu kwaye ukuqina kwe-blade kubi.Ngethuba lenkqubo yokusika, i-saw blade ixhomekeke kwi-vibration kunye nokuphambuka, okubangela ukungahambi kakuhle kwe-workpiece yokusikwa.

4. Izinto ezichaphazela ukusebenza kakuhle kunye nobomi beiincakuba zesarha zedayimani ezijikelezayo

Izinto ezichaphazela ukusebenza kakuhle kunye nobomi beiincakuba zesarha zedayimani ezijikelezayozibandakanya iiparamitha zenkqubo yokusika, ibakala ledayimani, ubungakanani bamasuntswana, ugxininiso, kunye nobulukhuni bebhondi.

1. Iiparamitha zokusarha

(1) Isarha yokusika isantya

Kumsebenzi osebenzayo, isantya somgca weiincakuba zesarha zedayimani ezijikelezayouthintelwe yimeko yezixhobo, umgangatho we-saw blade, kunye neempawu zelitye ezisarha.Ngokubhekiselele kubomi benkonzo kunye nempumelelo yokusika i-saw blade, isantya somgca we-saw blade kufuneka sikhethwe ngokusekelwe kwiipropati zamatye ahlukeneyo.

(2) Ubunzulu bokusarha

Ngaphakathi koluhlu oluvumelekileyo lokusebenza komatshini kunye namandla esixhobo, ubunzulu obukhulu bokusika kufuneka bukhethwe ngokusemandleni ukuphucula ukusika ukusebenza kakuhle.Xa kukho iimfuno zomgangatho womatshini, ukusika ubunzulu obuncinci kufuneka kusetyenziswe.

(3) Isantya sokutya

Isantya feed isantya feed ilitye isarha.Ixabiso layo kufuneka likhethwe ngokusekelwe kwiipropati zelitye eliqingqiweyo.Ngokubanzi, ukubona amatye athambileyo, anje ngebhastile, kunokonyusa ubunzulu besarha kunye nokunciphisa isantya sokutya, nto leyo enceda kakhulu ekuphuculeni izinga lokusarha.Ukusarha igranite ecolekileyo kunye nehomogeneous noko kunokunyusa isantya sokutya ngokufanelekileyo.Ukuba isantya sokutya sisezantsi kakhulu, iblade yedayimani icolwa ngokulula.Nangona kunjalo, xa usarha igranite ngesakhiwo sengqolowa erhabaxa kunye nobunzima obungalinganiyo, isantya sokusika kufuneka sincitshiswe, kungenjalo kuya kubangela ukuba i-saw blade ingcangcazele kwaye ibangele ukuqhekeka kwedayimani, ngaloo ndlela kuncitshiswe isantya sokusika.

2. Ubungakanani besuntswana ledayimani

Ubungakanani besuntswana ledayimane elisetyenziswa ngokuqhelekileyo ukusuka kwi-30/35 ukuya kwi-60/80 mesh.Ubunzima belitye, ubukhulu beqhekeza kufuneka bukhethwe.Ngenxa yokuba phantsi kweemeko ezifanayo zoxinzelelo, i-diamond ecolekileyo, iyancipha ngakumbi, enenzuzo yokusika kumatye anzima.Ukongeza, ubukhulu becala ubukhulu be-saw blades bufuna ukusebenza kakuhle kokusika, kwaye ubungakanani besuntswana elirhabaxa njenge-30/40 mesh kunye ne-40/50 mesh kufuneka kukhethwe;Idayamitha encinci yeesarha iiblawudi zinobuchule obuphantsi bokusika kwaye zifuna amacandelo agudileyo wokusika amatye.Kucetyiswa ukuba ukhethe ubungakanani beencinci ezincinci, ezifana ne-50/60 mesh kunye ne-60/80 mesh.

3. Ugxininiso lwedayimani

Ugxininiso lwedayimani lubhekiselele kubuninzi bedayimani yosasazo kwimatriki yomaleko osebenzayo.Ngokutsho kwemimiselo, ukuxinwa kwe-4.4 carats yedayimane nge-cubic centimeter ye-matrix ye-work layer yi-100%, kwaye i-concentration ye-3.3 carats yedayimane yi-75%.Umthamo womthamo ubonisa umthamo wedayimane kwibhloko kwaye ichaza ukuba i-concentration yi-100% xa umthamo we-diamond ubala i-1/4 yomthamo opheleleyo.Ukonyusa umdibaniso wedayimani kulindeleke ukuba kwandiswe ubomi beblade yesarha, njengoko ukonyuka koxinzelelo kunciphisa umndilili wokusika ngedayimani nganye.Kodwa ukwandisa ugxininiso kuya kwandisa ixabiso le-saw blade, ngoko kukho ugxininiso olunoqoqosho olunyukayo ngokunyuka kokusebenza ngokufanelekileyo.

4. Ukuqina kwesibophelelo sentloko yomsiki:

Ngokuqhelekileyo, okukhona ukuqina kokuqina kwebhondi, kokukhona komelele ukuxhathisa kwayo ukunxiba.Ngoko ke, xa ubona amatye nge-abrasiveness ephezulu, ubunzima be-binder buphezulu ngokulula;Xa ubona amatye athambileyo, ubunzima be-binder kufuneka bube buphantsi;Xa ubona amatye ane-abrasiveness ephezulu kunye nobunzima, ubunzima be-binder kufuneka bube yimodareyitha.

5, iNdlela yoPhuhliso yeIdayimani yeeSarha zeSetyhula zeSarha

Iincakuba zesarha zedayimani ezijikelezayozizixhobo eziphambili kwishishini lokulungisa amatye.Kwiminyaka yakutshanje, inani ledayimani ezenziweyo ezisetyenziswa kwishishini lokulungisa amatye linyuke kakhulu, kwaye ukusetyenziswa kweiincakuba zesarha zedayimani ezijikelezayonayo iyanda.Ngokubanzi, uphuhliso lweiincakuba zesarha zedayimani ezijikelezayozombini ngaphakathi nangaphandle inezi mpawu zilandelayo: ukuvelisa iincakuba zeesarha ezisebenzayo nezikumgangatho ophezulu, kunye nokuphuhlisa iidayimani ezikhethekileyo zodidi lwesarha;Nika ingqalelo ngakumbi kuphando lwe powder, matrix, kunye nenkqubo ye-sintering;Nika ingqalelo ngakumbi kuphando kwi-sawability kunye ne-sawing mechanism yezixhobo zamatye;Laser welding blade iye yaphuhliswa;Phuhlisa ubungakanani obukhuluiincakuba zesarha zedayimani ezijikelezayo.Okwangoku, ukusetyenziswa kweiincakuba zesarha zedayimani ezijikelezayoiya isanda.Kwixesha elizayo, ulwalathiso lophuhliso lweiincakuba zesarha zedayimani ezijikelezayokukuphucula ukusebenza kakuhle kokusika, ubomi beblade, ukunciphisa iindleko zemveliso, kunye nokufezekisa ukhuseleko lokusingqongileyo.

Isalathiso: "I-Diamond kunye neDayimane yeZixhobo zoLwazi lweQ&A" nguZhang Shaohe kunye noHu Yule

Ixesha lokuposa: Aug-04-2023