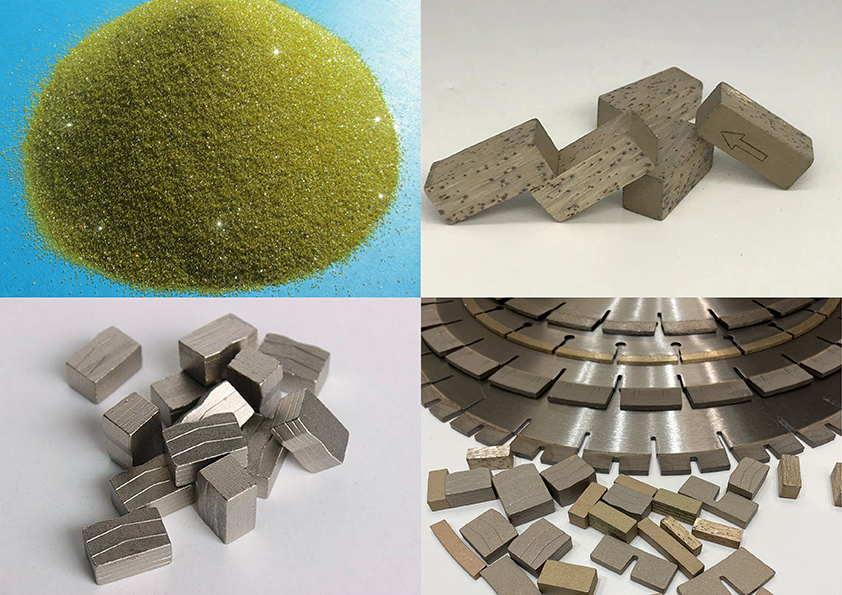

1.Ithini indima yelungu ngalinye kwibhinda yesarha yedayimane yematrix?

Indima yobhedu: I-alloys esekwe kwi-Copper kunye ne-copper zezona zintsimbi zisetyenziswa kakhulu kwi-metal binder diamond izixhobo, kunye ne-electrolytic copper powder yeyona isetyenziswa kakhulu.Iialloyi ezisekelwe kubhedu kunye nobhedu zisetyenziswa kakhulu ngenxa yokuba izibophelelo ezisekelwe kubhedu zineepropati ezanelisayo ezibanzi: ubushushu obuphantsi be-sintering, ukubunjwa okulungileyo kunye nokungabizi, kunye nokungahambi kakuhle kunye nezinye izinto.Nangona ubhedu lungenakumanzisa iidayimani, izinto ezithile kunye neealloyi zobhedu zinokukuphucula ngokubonakalayo ukumanzi kwazo kwiidayimani.Enye yezinto ezifana neCr, Ti, W, V, Fe eyenza ubhedu kunye ne-carbides ingasetyenziselwa ukwenza i-alloys yobhedu, enokunciphisa kakhulu i-angle yokumanzisa i-alloys zethusi kwiidayimani.I-solubility yobhedu kwintsimbi ayiphezulu.Ukuba kukho ubhedu olugqithisileyo kwisinyithi, kunciphisa ngokukhawuleza ukusebenza kobushushu kwaye kubangela ukuqhekeka kwezinto.Ubhedu lunokwenza izisombululo ezahlukeneyo eziqinileyo nge-nickel, i-cobalt, i-manganese, i-tin, kunye ne-zinc, ukomeleza isinyithi se-matrix.

Umsebenzi we-tin: I-Tin yinto enciphisa ukuxinezeleka komphezulu we-alloys engamanzi kwaye ibe nefuthe lokunciphisa i-angle yokumanzisa yealloyi zolwelo kwiidayimani.Yinto ephucula ukumanzisa kweentsimbi ezibotshiweyo kwiidayimani, kunciphisa indawo yokunyibilika kwee-alloys, kunye nokuphucula ukubunjwa kokucinezela.Ngoko i-Sn isetyenziswa ngokubanzi kwi-adhesives, kodwa ukusetyenziswa kwayo kulinganiselwe ngenxa yokwandiswa kwayo okukhulu.

Indima ye-zinc: Kwizixhobo zedayimane, i-Zn kunye ne-Sn zinezinto ezininzi ezifanayo, ezifana nendawo encibilikayo ephantsi kunye nokukhubazeka okulungileyo, ngelixa i-Zn ingekho kakuhle ekutshintsheni ukumanzi kwedayimane njenge-Sn.Uxinzelelo lwe-vapor yensimbi ye-Zn luphezulu kakhulu kwaye kulula ukwenza i-gasify, ngoko ke kubalulekile ukuhlawula ingqalelo kwinani le-Zn elisetyenziswe kwi-diamond tool binders.

Indima ye-aluminiyam: I-aluminiyam yesinyithi yintsimbi ebalaseleyo yokukhanya kunye ne-deoxidizer elungileyo.Kwi-800 ℃, i-angle yokumanzisa ye-Al kwidayimani yi-75 °, kwaye kwi-1000 ℃, i-angle yokumanzisa yi-10 °.Ukongeza i-aluminium powder kwi-binder yezixhobo zedayimani kunokwenza isigaba se-carbide Ti Å AlC kunye ne-intermetallic compound TiAl kwi-matrix alloy.

Indima yentsimbi: I-Iron inendima emibini kwi-binder, enye kukwenza i-carburized carbides kunye nedayimani, kwaye enye i-alloy kunye nezinye izinto zokuqinisa i-matrix.Ukumanzisa kwentsimbi kunye nedayimane kungcono kunobhedu kunye ne-aluminium, kwaye umsebenzi wokubambelela phakathi kwentsimbi kunye nedayimane uphezulu kunolo lwe-cobalt.Xa isixa esifanelekileyo sekhabhoni inyibilika kwii-alloys ezisekelwe kwi-Fe, kuya kuba luncedo ekudibaneni kwabo kunye nedayimane.Ukukrolwa okuphakathi kwedayimani nge-alloys ezisekelwe kwi-Fe kunokunyusa amandla okudibanisa phakathi kwebhondi kunye nedayimani.I-fracture surface ayigudi kwaye ingenanto, kodwa igutyungelwe ngumaleko we-alloy, oluluphawu lwamandla okudibanisa okuphuculweyo.

Indima ye-cobalt: I-Co kunye ne-Fe iyinxalenye yeqela leenguqu, kwaye iimpawu ezininzi ziyafana.I-Co inokwenza i-carbide Co ₂ C ngedayimane phantsi kweemeko ezithile, ngelixa isasaza ifilimu ye-cobalt encinci kakhulu kumphezulu wedayimane.Ngale ndlela, i-Co inokunciphisa ukungavisisani kwangaphakathi phakathi kwe-Co kunye nedayimane, kwaye inomsebenzi obalulekileyo wokuncamathela kwidayimani kwinqanaba lolwelo, iyenze ibe yeyona nto ibalaseleyo yokudibanisa.

Indima yenikeli: Kwi-binder yezixhobo zedayimani, i-Ni yinto eyimfuneko.Kwi-alloys esekelwe kwi-Cu, ukongezwa kwe-Ni kunokunyibilika ngokungenasiphelo kunye ne-Cu, ukomeleza ingxubevange ye-matrix, ukucinezela ilahleko yentsimbi ephantsi yokunyibilika, kunye nokwandisa ukuqina kunye nokumelana nokunxiba.Ukongeza i-Ni kunye ne-Cu kwii-alloys ze-Fe kunokwehlisa ubushushu be-sintering kunye nokunciphisa ukubola kwe-thermal yeentsimbi ezibophelelwe kwiidayimani.Ukukhetha indibaniselwano efanelekileyo ye-Fe kunye ne-Ni inokuphucula kakhulu amandla okubamba i-Fe based binders kwiidayimani.

Indima ye-manganese: Kwizibophelelo zetsimbi, i-manganese inefuthe elifanayo nentsimbi, kodwa inokungena okunamandla kunye nokukwazi ukukhupha umoya, kwaye iyakwazi ukukhupha i-oxidation.Isixa esongezelelweyo seMn ngokuqhelekileyo alikho phezulu, kwaye eyona nto iphambili kuqwalaselo kukusebenzisa i-Mn ye-deoxidation ngexesha le-sintering alloying.UMn oseleyo unokuthatha inxaxheba kwi-alloying kunye nokuqinisa i-matrix.

Indima yechromium: I-Metal chromium yinto eyomeleleyo eyenza i-carbide kwaye ikwayinto esetyenziswa ngokubanzi.Kwi-diamond groove saw blade matrix, kukho ichromium eyaneleyo yokuba nesandi sokuthomalalisa isandi, esinxulumene nokusebenza kwamandla kaCr.Ukongeza ixabiso elincinci le-Cr kwi-matrix esekelwe kwi-Cu kunokunciphisa i-angle yokumanzisa i-alloy esekelwe kubhedu kwi-diamond kunye nokuphucula amandla okubopha kwi-alloy esekelwe kwi-alloy kwi-diamond.

Indima ye-titanium: I-Titanium yinto eyomeleleyo yokwenza i-carbide ekulula ukuyi-oxidize kwaye kunzima ukuyinciphisa.Phambi kweoksijini, i-Ti ivelisa ngokukhethekileyo i-TiO2 endaweni ye-TiC.Isinyithi se-Titanium sisixhobo esilungileyo solwakhiwo olunamandla aqinileyo, ukunciphisa amandla amancinci kumaqondo obushushu aphezulu, ukuxhathisa ubushushu, ukuxhathisa ukubola, kunye nendawo ephezulu yokunyibilika.Uphando lubonise ukuba ukongeza isixa esifanelekileyo se-titanium kwi-diamond saw blade matrix kunenzuzo ekuphuculeni ubomi benkonzo ye-saw blade.

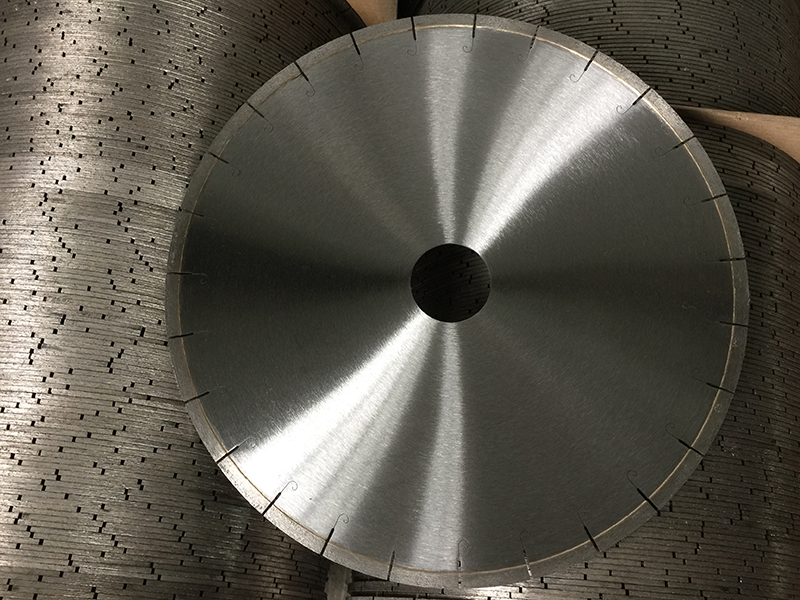

2.Kutheni le nto umzimba wesarha kufuneka uhambelane nelitye lokusika?

Iindlela eziphambili zokuqhekeka kwamatye ngexesha lenkqubo yokusika i-saw blade yi-fracturing kunye nokutyumza, kunye nokucheba umthamo omkhulu kunye nokuqhekeka, okongezwa ngokusila komhlaba.Idayimani enomgangatho osebenzayo we-serrated osebenza njengesixhobo sokusika.Ukunqunyulwa kwayo kuyindawo yokukhupha, indawo yokusika iphambi komda, kwaye indawo yokugaya isemva.Ngaphantsi kokusika kwesantya esiphezulu, iincinci zedayimane zisebenza kwinkxaso ye-matrix.Ngethuba lenkqubo yokusika ilitye, kwelinye icala, idayimane ifumana i-graphitization, i-fragmentation, kunye ne-detachment ngenxa yokushisa okuphezulu okwenziwa yi-friction;Kwelinye icala, i-matrix inxitywa kukungqubana kunye nokukhukuliseka kwamatye kunye nomgubo wamatye.Ke ngoko, umba wokuguquguquka phakathi kwee-saw blades kunye namatye ngokwenene ngumba wexabiso lokunxiba phakathi kwedayimani kunye ne-matrix.Uphawu lwesixhobo esisebenza ngokuqhelekileyo kukuba ilahleko yedayimane ihambelana nokunxitywa kwe-matrix, ukugcina idayimani ikwimeko eqhelekileyo yokusika, ingeyiyo i-detachment ngaphambi kwexesha okanye ukuguba kwedayimani egudileyo kunye nemtyibilizi, iqinisekisa ukuba isiphumo sayo sokusila sisetyenziswa ngokupheleleyo. ngexesha lokusebenza, okukhokelela ekubeni iidayimani ezininzi zibe kwimeko eqhekekileyo kwaye egugile.Ukuba amandla kunye nokuchasana kwempembelelo yedayimane ekhethiweyo kuphantsi kakhulu, kuya kukhokelela kwinto "yokucheba", kwaye ixesha lokuphila kwesixhobo liya kuba liphantsi kwaye i-passivation iya kuba nzima, kwaye i-sawing ayiyi kuhamba;Ukuba kukhethwe amaqhekeza aphezulu kakhulu abrasive, i-cut cut of abrasive particles iya kubonakala kwisimo esicwangcisiweyo, okubangela ukwanda kwamandla okusika kunye nokunciphisa ukusebenza kakuhle.

(1) Xa isantya sokunxiba sematriki sisikhulu kunedayimani, sikhokelela ekusikeni kwedayimani ngokugqithisileyo kunye nokuphuma kwangaphambi kwexesha.Ukumelana nokunxiba komzimba we-saw blade kuphantsi kakhulu, kwaye ubomi be-saw blade bufutshane.

(2) Xa isantya sokunxiba sematriki singaphantsi kwedayimani, idayimani entsha ayivezwa lula emva kokuba umda wedayimani ugugile, iiserati azinawo umphetho wokusika okanye umda wokusika uphantsi kakhulu, umphezulu wedayimani. i-serrations idluliswa, isantya sokusika sicotha, kwaye kulula ukubangela ukuba ibhodi yokusika iwe, echaphazela umgangatho wokucubungula.

(3) Xa isantya sokunxiba sematrix silingana nesantya sokunxiba sedayimani, sibonisa ukuhambelana kwematrix ngelitye elisikiweyo.

Ixesha lokuposa: Aug-11-2023