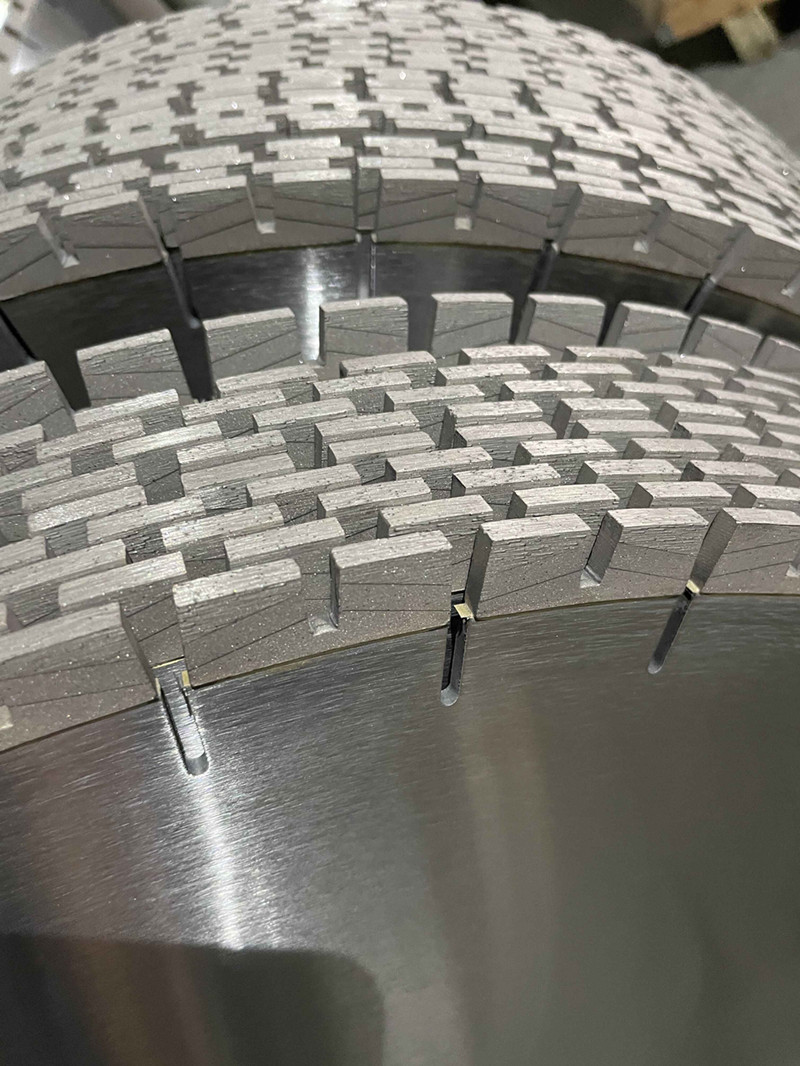

1.Hlola ububanzi obungaphakathi nangaphandle bee-saw blades, ubukhulu kunye nenani lamazinyo e-substrate ngokweemfuno zokuvelisa, kwaye ukhangele ukucaciswa, ubuninzi kunye ne-radian yecandelo ledayimane.Emva koko ugaye i-chamfer yangaphandle ye-substrate kwisixhobo sokugqoka.Coca i-welding surface yesiseko kunye necandelo kunye ne-C switch, kwaye usebenzise i-agent agent.

2.Khetha i-welding blade efanelekileyo ngokweenkcukacha ze-saw blade kwiimfuno zokwakha.Ububanzi beblade ye-welding ngokuqhelekileyo yi-0 enkulu kunobukhulu besiseko.Ubunzima be-welding blade buya kuba yi-0.25-0.30mm xa udibanisa i-saw blade kunye nobubanzi be-5-1 mm nangaphezulu kwe-1500mm;Xa welding blade isarha ububanzi ngaphantsi kwe 1500mm, ubukhulu beblade welding iya kuba 0.15 ~ 0.25mm.

3.Faka isiseko, ulungelelanise indawo, qinisa izikhonkwane zokulungisa, ubeke kwindawo yokupholisa, ulungelelanise isixhobo sokutyhala icandelo kunye ne-segment clamp, ulungelelanise ubushushu be-welding, ukugcinwa kobushushu kunye nexesha lokupholisa ngokweemfuno zenkqubo, kwaye ufezekise. ukuwelda.

4.Xa udibanisa i-saw blade ngezixhobo eziphezulu ze-frequency, jikelisa isiseko se-180 ° C kwicandelo ngalinye elidityanisiweyo, ukwenzela ukuba i-weld symmetrically igweme i-annealing okanye i-deformation yendawo ebangelwa ukugqithiswa kwesiseko.

5.Xa welding i-gang saw blade, weld icandelo kwindawo echaziweyo ngokwendlela yezinyo.

6. Emva kwe-welding i-saw blade, ukuzihlola kuya kwenziwa.

Ixesha lokuposa: Mar-04-2023